In its production facility, Mediteran Inox uses advanced equipment that, in addition to the regular production of machines and equipment, also offers CNC services for material processing by milling and turning. CNC processing is a production process where the raw material is removed with precise cutting tools in order to make the desired part or product.

In our production, we use top technology in the machining service:

Mašinski Park

Hurco VM20

3 axes

Winmax

X – 1020mm

Y – 457mm

Z – 550mm

Hurco VMX 24

3 axes

Winmax

X – 610mm

Y – 510mm

Z – 760mm

Hurco VMX 24

3 axes

Ultimax

X – 610mm

Y – 520mm

Z – 760mm

Hurco VMX 42

3 axes

Ultimax

X – 1067mm

Y – 610mm

Z – 750mm

Hurco VMX 42

3 axes

Ultimax

X – 1010mm

Y – 510mm

Z – 750mm

Hurco VMX 50

3 axes

Ultimax

X – 1270mm

Y – 650mm

Z – 760mm

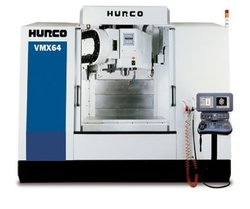

Hurco VMX 64

3 axes

Ultimax

X – 1620mm

Y – 860mm

Z – 870mm

Hurco VMX 64

3 axes

Ultimax

X – 1620mm

Y – 860mm

Z – 870mm

Hurco VMX 42 SR

5 axes

Winmax

X – 1067mm

Y – 610mm

Z – 500mm

B – 92°

C – 360°

Y – 610mm

Z – 500mm

B – 92°

C – 360°

Hurco VMX 42 SR

5 axes

Winmax

X – 1067mm

Y – 610mm

Z – 500mm

B – 92°

C – 360°

Y – 610mm

Z – 500mm

B – 92°

C – 360°

Okuma LU15 MW

4 axes

turning diameter 270mm max.

spindle bore for pole work 52mm